Xenolith

Installation & Product Guide

Instructional Videos

Download the Xenolith Installation guide

Standard tools can be used for machining and processing such as sawing, drilling, and routing.

Neither the surface nor exposed edges need to be protected or sealed.

polytec Xenolith is a very hard material. Use high-quality screws and ensure to predrill pilot holes or follow the directions recommended by the screw manufacturer. Be cautious not to overtighten.

Screws should be carefully positioned to prevent splintering (minimum 20mm to edge). Screwing directly into the edge of a panel is not recommended. Metal brackets are recommended when fixing two panels together. Mitring of edges should be avoided as they are vulnerable to damage; a chamfered edge or crescent-shaped edge will avoid edge chipping.

To achieve optimum finishing, always use trial pieces to test before actual operation. Always ensure the decorative surface is facing upwards to prevent damage and chipping of the edges.

For routing edges, use a hard metal or diamond cutter at a slow speed to achieve proper finishing without burn marks. This can be done using a CNC machine or manually operated tooling.

| Bit Diameter (mm) | No. of Revolutions (rev/min) | Speed (m/s) | Feeding Speed (m/min) |

|---|---|---|---|

| 20 | 18000 | 20 | 5 |

| 25 | 24000 | 30 | - |

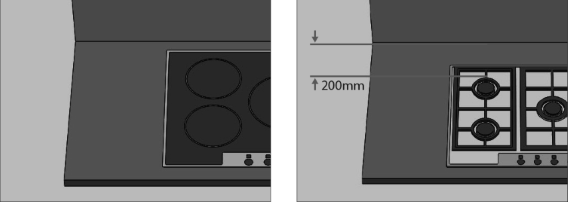

polytec Xenolith can be used as a splashback. For heat and cleaning requirements, use full sheets wherever possible to avoid joins. Adhere to the minimum clearance guidelines for electric or gas cooktops: